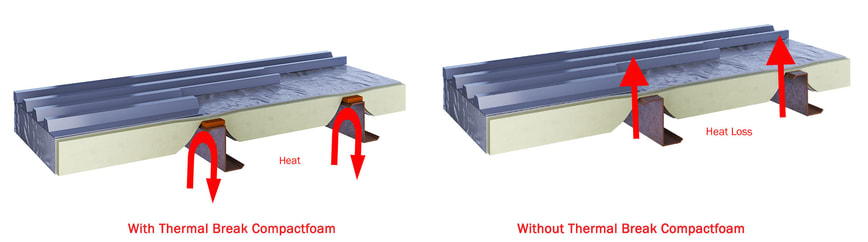

Window buck thermal break. Column base thermal break. Thermal spacer block. Compacfoam thermal break material reduces conductive heat loss due to thermal bridging. It provides continuous insulation where structural connections would normally create a thermal bridge in the thermal control layer of the building envelope.

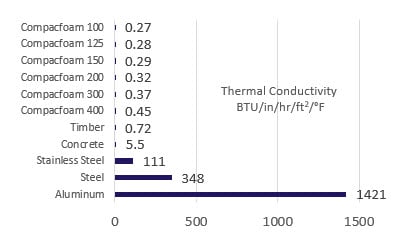

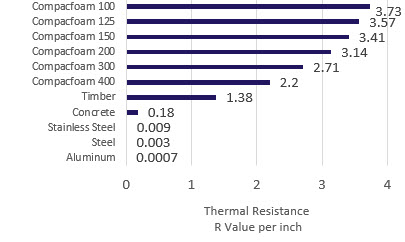

This thermal break material conducts heat up to 5,000 times less than aluminum, 1,300 times less than steel and 20 times less than concrete. It is compatible with all field applied air barriers, sealants, and flashings.

In addition to being red list free, this EPS type thermal break material is manufactured with a blowing agent that has an ODP (ozone depleting potential) of zero and a GWP (global warming potential) of five. It is HCFC and CFC free and contains zero HBCD (halogenated fire retardants).

• Fenestration Frames and Openings

• Roof and Wall Purlin Connections

• Curtain wall and Storefront Transitions

• Column Bases

Compacfoam is manufactured in a wide range of densities to control deflection and creep in application. This also corresponds to a range of material R-values from R 2.2 to R 3.7 per inch.

Compacfoam is used as thermal spacer blocks in metal building wall and roof panel connections.

Compacfoam thermal break at window frame connection within the wall opening. The window frame is fully supported within the opening by Compacfoam thermal break material. In the this position, the frame and glazing are located within the wall framing and the opening is free of thermal bridging.

Compacfoam thermal break at window opening. The window frame is fully supported within the exterior insulation by Compacfoam thermal break material. In the this position, the frame and glazing are located within the thermal envelope and the opening is free of thermal bridging.

Compacfoam can be cut and machined to integrate with window and door sills or thresholds

Compacfoam is used as a thermal break in rough openings and as a load supporting buck around the opening reducing thermal bridging between window/door frames and steel stud wall construction.

Compacfoam can also be used as a thermal break at curtain wall transitions, storefront sill plates and as a column base thermal break in cold storage and freezer room applications.