Thermal Break Materials

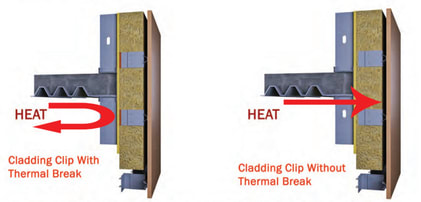

Thermal break materials reduce the heat lost due to thermal bridging. Structural thermal breaks maintain continuous insulation where connections pass through the thermal envelope. Additionally, a thermal break will keep internal material surface temperatures warm, which avoids the risk of condensation within the building envelope.

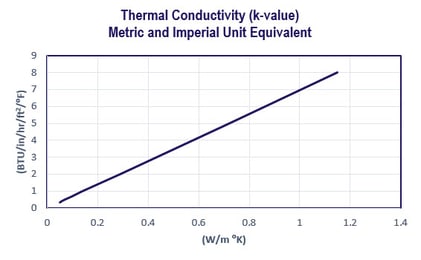

The conductance and thermal conductivity of a thermal break determine how well it conducts heat and the rate at which heat will flow through it. The thermal conductivity or k-value is often presented in either metric or imperial units. Figure 1 will help when comparing thermal break materials or assemblies that publish only one or the other. The graph shows the relationship between metric and imperial units of thermal conductivity.

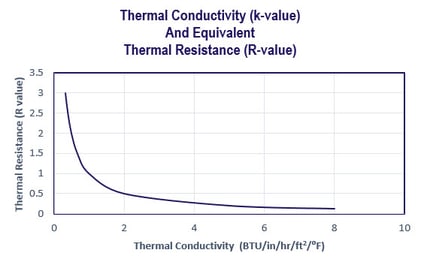

The thermal resistance of a material or R-value, is the inverse of it’s thermal conductivity. The graph in Figure 2 shows the relationship between R-value and k-value in imperial units.

Figure 1

Figure 2

LEED Opportunities

Energy & Atmosphere (EA)

EA Prerequisite 2: Minimum Energy Performance. Reduces excessive energy use by achieving energy efficiency.

EA credit: Optimize Energy Performance.

Our thermal break materials help reduce building energy demand by minimizing heat flow through the building envelope. This increases the effective R value of wall and roof assemblies.

Materials & Resources (MR)

MR credit: Sourcing of raw materials (recycled content). Encourages the use of products and materials that have life cycle impacts.

Compacfoam ECO thermal break material is made with 99% pre-consumer content and can contribute to recycled content credits.

MR credit: Material Ingredients. Encourages the use of products and materials that minimize the use of or generate harmful substances and have improved life cycle impacts.

All of our thermal break materials are red list free and our foam based products are manufactured with blowing agents that have an ODP of 0 and a GWP of 5 or less. They are HCFC and CFC free and contain 0 HBCD.

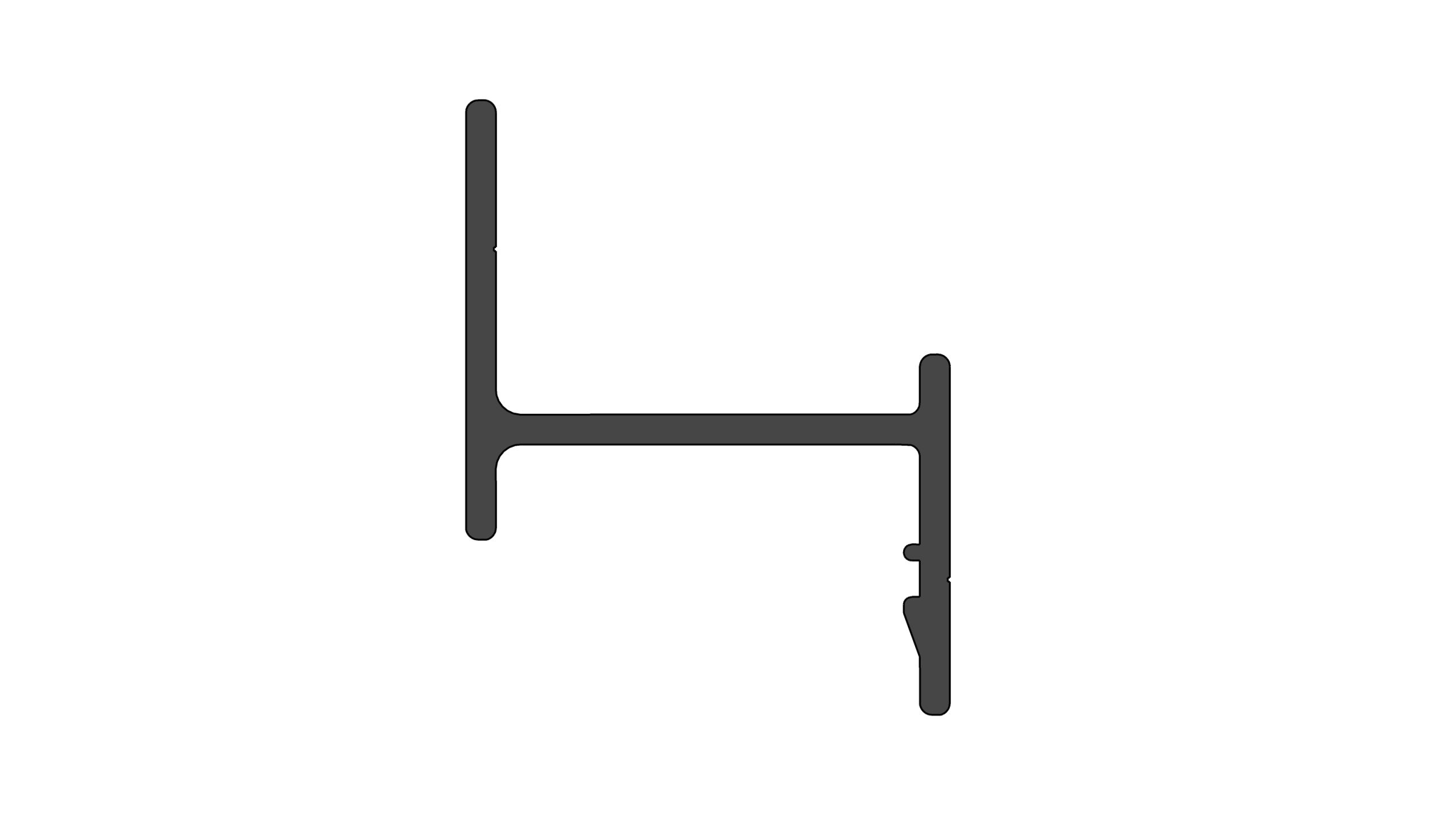

If you have a technical question about any of our structural thermal break products or thermal bridging solutions in general, please contact us to discuss. Click on the images below for additional information on each type of thermal break and the locations within the building envelope where they can be used to prevent thermal thermal bridging.

Thermal break blocks reduce heat loss at foundation to wall transitions and roof to parapet intersections.

A high strength thermal break material that reduces heat loss at balcony, canopy, shelf angle, roof post and other structural steel connections.

A non-combustible thermal break material that reduces heat loss at cladding attachment, sunshade and roof post connections.

A non–combustible thermal break material that reduces heat loss at roof purlin, wall purlin and window openings.

An EPS material combining strength and high thermal resistance reducing heat loss at window openings, roof or wall purlins, and curtain wall and storefront transitions.

Exo™ z girt thermal break cladding attachment is an FRP (fiberglass) pultruded composite made with a custom fire-retardant resin system.