Thermal Break Material

(TBM-1)

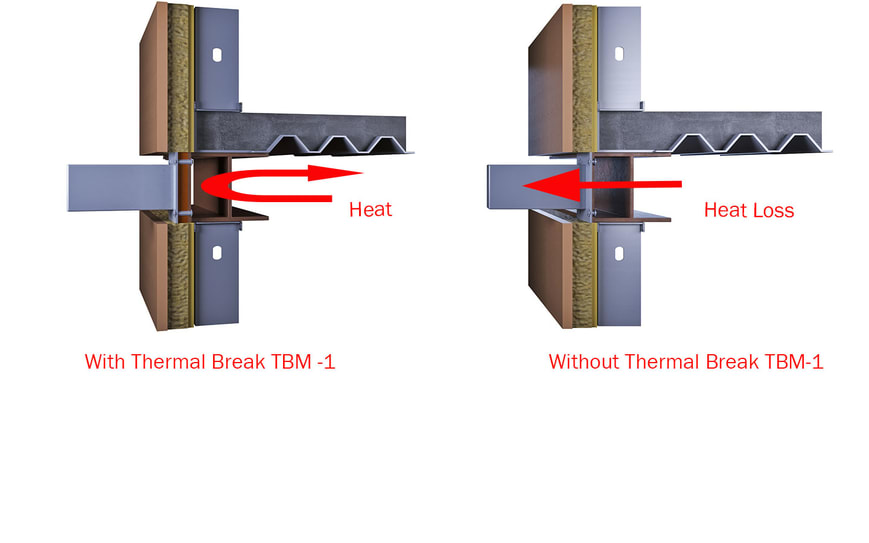

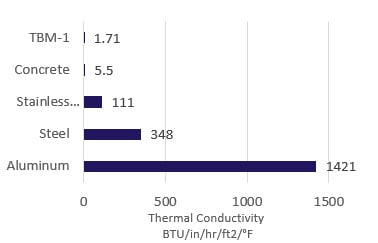

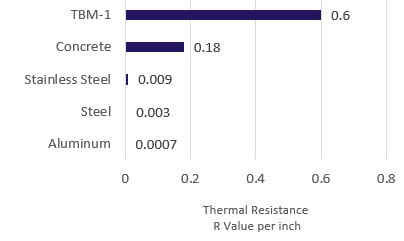

TBM-1 thermal break material conducts heat 820 times less than aluminum, 220 times less than steel and 65 times less than stainless steel. It is compatible with all field applied air barriers, sealants and flashings. Fabreeka-TIM and Armatherm FRR are equivalent to TBM-1.

The thermal conductivity of a material is a function of its conductance which helps determine the rate at which heat flows through that material. Heat flow is also dependent on area and temperature.

Conductance is a function of thickness, so to be effective at reducing heat flow through a bolted, steel connection, the thickness of the thermal break is important.

TBM-1 thermal break material is available in several thicknesses to accommodate a wide range of connection details. In any connection design, the goal is to use the appropriate thickness/area which helps meet energy code requirements for the wall or roof assembly.

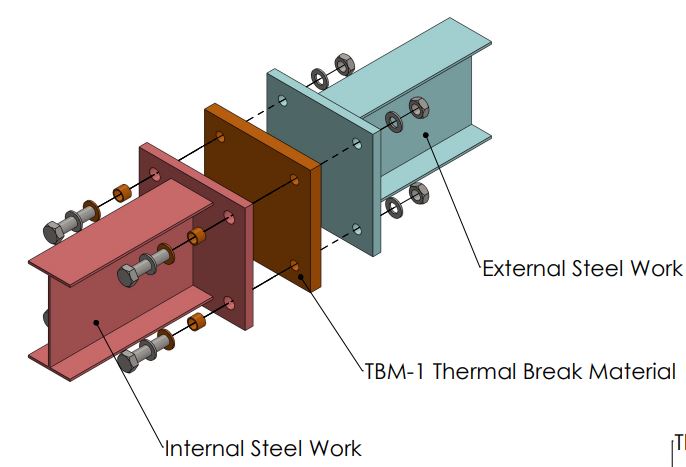

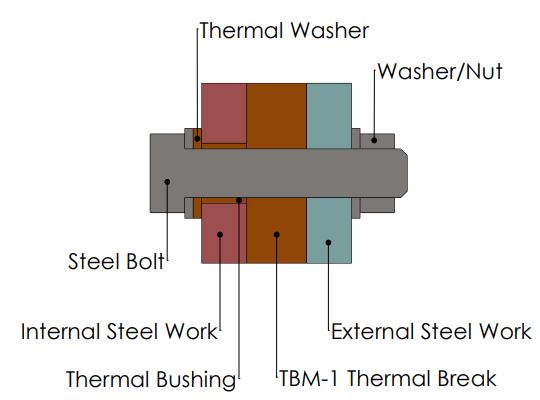

Specifying Thermal Break Materials for Bolted, Steel Connections

Designing Steel Connections with Thermal Break Materials

Roof post thermal break

Column base thermal break

Dunnage post thermal break