Thermal Break Solutions for Curtain Walls and Storefronts

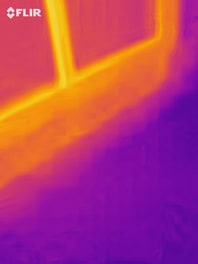

Curtain wall thermal break. Thermal bridging at curtain wall mullion and storefront framing connections increases their U-value. Heat loss through store front transitions occurs at the perimeter of the highly conductive frames where they are attached to the wall opening and foundation. This creates a potential condensation risk and a lower than expected R value for the wall assembly.

Wall transitions and anchor, mullion connections

Windows are necessary; however, they are the most inefficient portion of a building’s envelope – especially when the window to wall ratio is high as is the case with curtain wall systems. Windows exhibit much higher thermal transmittance than the opaque or clear field portion of a building’s walls.

Curtain wall and storefront U values however, do not include the heat loss created by thermal bridging at their transition and connection locations. The effect of the thermal bridging or the “installed” U value must be assigned to these features and accounted for in the energy efficiency of the building. Thermal modeling has shown that curtain wall transitions can reduce a wall’s effective R value by as much as 70%.

Thermally broken frames have improved the U values of curtain wall and storefront assemblies by reducing the conductivity of the frames from outside to inside. However, even the lower-conductivity framing can be compromised due to flashing details, masonry sills, lintels and mullion connections. In these instances, heat flows around the thermally broken frame, cooling internal surface temperatures.

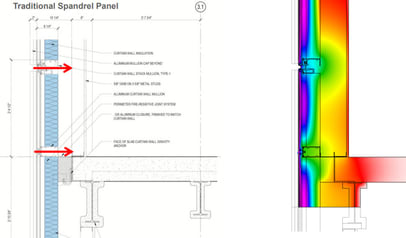

model credit: Payette

Thermal model of curtain wall attachment. Note the cooler temperatures within the insulated spandrel area due to heat transfer at the aluminum mullion connections. A dew point analysis will indicate whether condensation on material surfaces is a potential risk.

Curtain wall transitions and mullion attachment points within the spandrel area are sources of thermal bridging and heat transfer out of the building envelope. Thermal breaks can be incorporated between the pressure plate and structural mullion to improve the frame thermal efficiency; however, heat loss and potential condensation can be reduced further by using a structural thermal break at the mullion and/or clip connections to the main structure.

The framing of a storefront window is often recessed within a wall or installed flush with the exterior of the wall. In either case, the framing, including a door’s threshold can end up behind or in front of the thermal control layer of the wall. If the frame is thermally broken, it is then not properly aligned within the wall opening creating a heat loss path or thermal bridge around the frame connections.

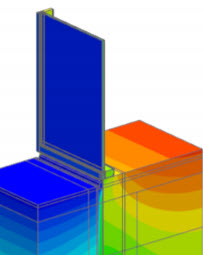

model credit: Morrison Hershfield

The subsills at the base of storefront systems should be installed on a structural thermal break to limit conductive heat loss from the subsill to the foundation.

Steel and aluminum have the ability to conduct heat at a high rate. Due to the thermal conductivity of these materials, they can easily transfer heat along structural connections that pass through the thermal envelope of a building. This is what creates thermal bridging and the resultant, higher than expected heat loss and lower than expected U values associated with curtain wall and storefront assemblies.

The “installed” U value of curtain walls and storefronts can be improved by using properly designed thermal breaks at framing, wall transition and mullion connections within the wall spandrel area. TBM-1, TBM-2 and Compacfoam structural thermal break solutions can be used in these areas to improve building envelope performance. The type of thermal break used is a function of loading conditions and thermal performance.

Conductance is a function of thickness and temperature difference, so the thickness of a thermal break should be carefully considered. In any connection design using a thermal break, the goal is to use the appropriate thermal conductivity that will help the wall assembly meet energy code requirements.