THERMAL BREAK MATERIAL

(TBM-3)

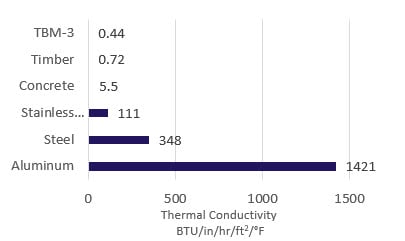

Window opening thermal break. Thermal Break Material (TBM-3) is a non- combustible thermal break that conducts heat 3,000 times less than aluminum, 1,000 times less than steel and 250 times less than stainless steel. For any material, conduction is a function of thickness and temperature difference, so the thickness of a thermal break material should be carefully considered.

The primary benefit of TBM-3 thermal break material is that it is non-combustible. As such, it is not necessary to conduct NFPA 285 or ASTM E119 fire testing when TBM-3 is incorporated in wall or roof assemblies.

It is an ideal thermal break for rough openings reducing thermal bridging between window/door frames and steel stud wall construction. Likewise, TBM-3 can be used as a thermal break at curtain wall transitions and storefront sill plates.

• NON-COMBUSTIBLE

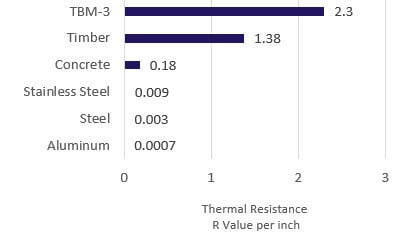

• Thermal resistance of R 2.2 per inch

• 0 Flame spread, 0 Smoke index

• Mildew, mold, rot and moisture resistant

• LBC Red List Free

The thermal conductivity of a material is a function of its conductance which helps determine the rate at which heat flows through that material. Heat flow is also dependent on area and temperature.

Conductance is a function of thickness, so to be effective at reducing heat flow through a bolted, steel connection, the thickness of the thermal break is important.

TBM-3 thermal break material is available in several thicknesses to accommodate a wide range of connection details. In any connection design, the goal is to use the appropriate thickness/area which helps meet energy code requirements for the wall or roof assembly.