What to know about substitution requests for thermal break materials in bolted steel connections. The purpose of this article is to clarify some common misunderstandings and offer some assistance with the substitution request approval process for all parties. How do you determine equivalency of thermal break materials?

Thermal breaks are not yet officially adopted into the ASHRAE 90.1model energy code or IECC standard nor are they currently accepted into the AISC or RCSC specifications. Do to this, it can be difficult for architects, owners, and engineers to specify them. Moreover, using thermal breaks is still a relatively new concept in North America to many, so how does a GC or subcontractor know when a substitution is equivalent to what has been specified?

Discussion points:

- “Or Approved Equal”

- Material Properties

- Proper Evaluation

“Or Approved Equal”

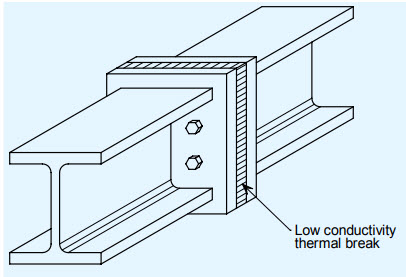

Continuous, exterior insulation became part of the ASHRAE 90.1 model energy code in 2007 to reduce heat loss due to thermal bridging in steel stud walls. Continuous, as defined by ASHRAE means “without thermal bridges other than fasteners.”

What happens when a balcony, canopy, or sunshade connection passes through the continuous insulation? The insulation is interrupted, and a thermal bridge is created, which lowers the R value of the wall assembly due to heat loss. A thermal bridge can also reduce the surface temperature of the materials inside the wall and create potential condensation risk.

We can reduce the heat loss due to thermal bridging by using a thermal break but what happens when the structural steel fabricator or GC want to substitute for the thermal break material that has been specified?

First, no matter what type of product we are discussing, we need to recognize that the phrases “or equal” and “or approved equal” can be confusing terms unless specifically defined in division 1 of the bid documents. That is because the products manufactured or supplied by different companies are very likely to never be exactly alike. So, they cannot be equal or identical. For example, all right angles are equal and identical because they must all have a base and height perpendicular by 90 degrees.

What then is the intent of the phrase “or approved equal” when it comes to thermal break materials for bolted steel connections?

The term “or approved equivalent” typically is what is meant by “or approved equal.” The term “equivalent” acknowledges that different products can serve the same purpose while having similar properties and produce the same results. Functionally, the products are equivalent. Here is why the wording in a specification matters:

“Or Equal”: Does not allow for the use of products that are perfectly acceptable but not “equal” meaning identical.

“Or Approved Equal”: Does not allow for acceptable but non “equal” products.

“Or Approved Equivalent”: Allows for the use of non “equal” but acceptable products and implies that review and approval by the architect/engineer is required.

AIA document A701-2018, article 3 “bidding documents”, section 3.3 “substitutions” clearly states:

“The materials, products and equipment described in the bidding documents establish a standard of required function, dimensions, appearance and quality to be met by any substitution. Where a ‘brand name or equal’ is stated in the bidding documents, the listing description is not intended to limit or restrict competition.”

The substitution process is critical to protecting design intent and allowing other appropriate products to be considered. Is the product being submitted suitable for the intended purpose? Is it truly equivalent? Below are some product equivalency considerations:

Function: Does the submitted product function the same as the specified product?

Appearance: Is the appearance the same as the specified product?

Quality: Is the quality equal or superior to the specified product?

Dimensions: Do the submitted products dimensions vary from the specified product, requiring revisions to drawings?

Longevity: Is the life expectancy of the proposed product equal or does it exceed the specified product?

Code Compliance: Is the proposed product approved by the applicable code authority?

Warranty: Does the proposed product’s warranty include equivalent terms?

Material Properties

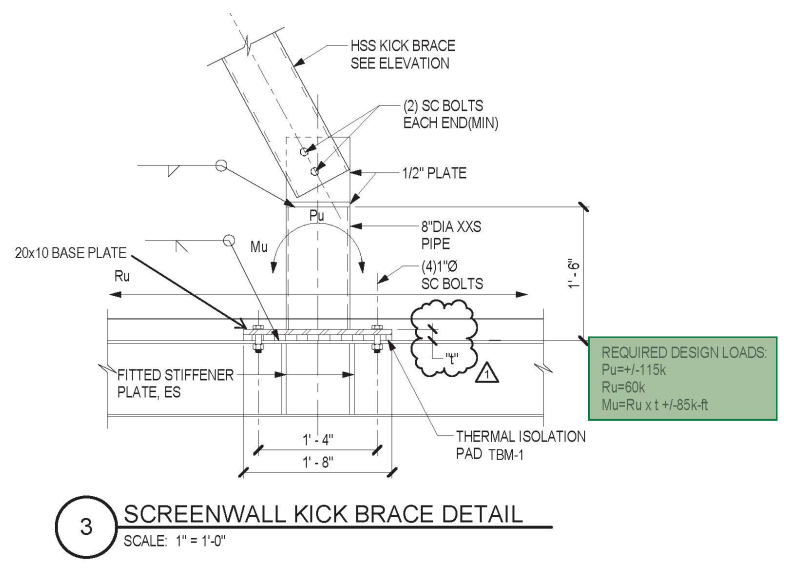

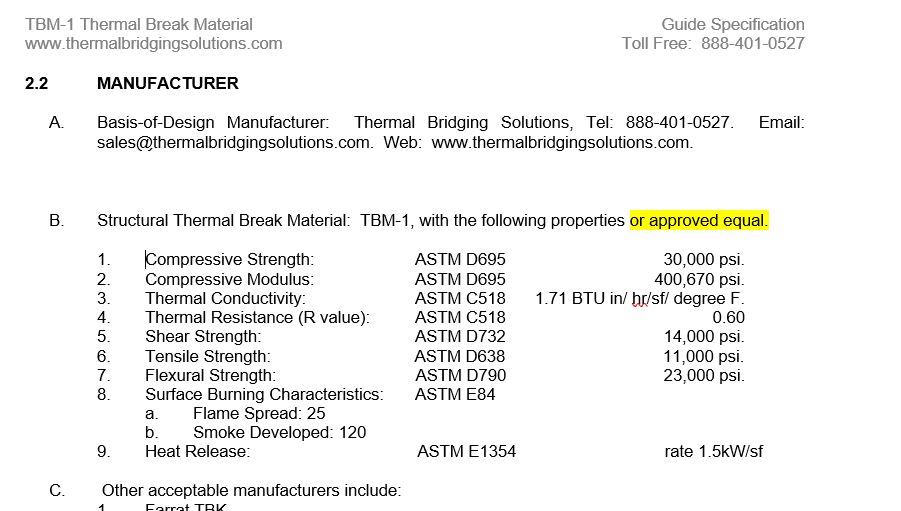

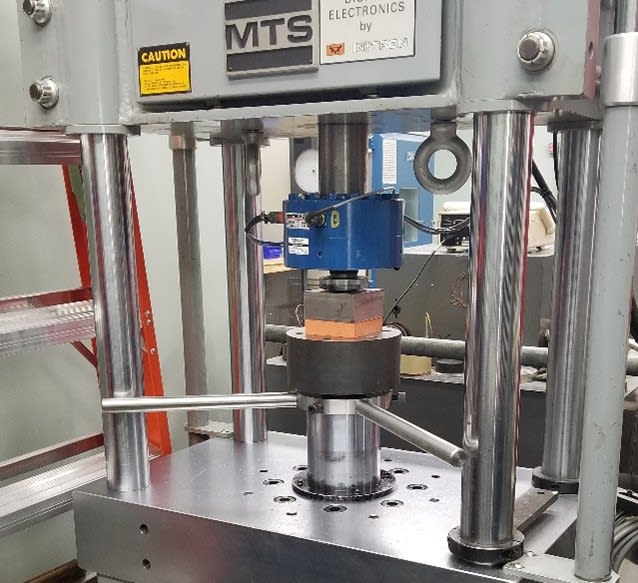

A material used as a thermal break becomes a load bearing element in a bolted, steel connection. It therefore must be capable of transferring normal, moment and shear forces without compromising the connection.

The most important characteristic to consider in a thermal break material is compression. When using a thermal break, the rotational stiffness of the connection/joint becomes a function of the material stiffness – as does the applied tension and potential bending stresses in the upper group of bolts. Likewise, the material stiffness in shear is important, especially as the thickness of the thermal break material increases for thermal efficiency, extending bolt length.

Perhaps most important of all is that the AISC/RCSC (Research Council on Structural Connections) standard “Specification for Structural Joints using High Strength Bolts” states that compressible materials shall not be placed within the grip of the bolts.

Image credit: Steel Construction Institute

It is therefore understood that thermal break materials used in bolted connections are not to compress. AISC and RCSC standards do not address materials other than steel so it is up to the engineer to decide how they will incorporate checks in the design process for the inclusion of a thermal break material.

When specifying a thermal break material in a bolted steel connection, calculations must be made using the material properties to confirm that there is no compression or additional rotation added in the connection. The SE will either use ASD or LRFD design methodology to determine this.

As mentioned earlier, products manufactured or supplied by different companies are very likely to never be exactly alike. So, they will not be equal or identical. Structural thermal break materials have different physical properties. Some values are higher and some lower in comparison to one another.

What about just comparing the physical properties to determine equivalency? Isn’t exact duplication of properties necessary? The answer is NO to both. Comparing the physical properties is not an acceptable method of determining whether a thermal break material is equivalent to the one specified. Why?

Evaluating a substitution for equivalency comes down to the original calculations using the material physical properties. It is the connection calculations that reveal whether a proposed material meets the design intent or not – not a direct comparison of the material properties themselves. Why is this important?

The majority of moment, bearing type connections incorporating thermal break materials, create a stress on the thermal break material of 2,000 psi or even less. Some are as low as 500 psi. In rare instances, perhaps 3,000 psi. These values can be 15x to 60x lower than the compressive strengths of thermal break materials.

One of the current misunderstandings in the sub request process is when a specification states a compressive strength or modulus of “X”, it does not mean that “X” is required to meet the design intent. What is required is to prove that there will be no compression in the connection or that the proposed material meets the minimum factor of safety using the ASD design method.

The compressive strength of a material only indicates the stress at which a material fails, not how much it compresses on its way to failure.

The Young’s modulus (compression modulus) and shear modulus, indicate how stiff a material is by measuring compression (strain) as a function of stress. The question is, at stresses lower than 2,000 psi, is there any compression at all? There can never be “zero strain” or zero compression, there is always a value even if that value is extremely small. What is critical is the point on a stress/stain curve where compression due to an increase in strain is no longer negligible and becomes significant. Can we tell this by comparing properties on product data sheets?

Comparing properties does not answer the question of equivalence – calculations are required. Just because a proposed material has a lower compression modulus, does not mean it will not meet the design criteria. For additional discussion on structural design methodology click here.

Evaluation of Thermal Break Materials and Proposed Substitutions

Evaluating substitution requests takes time and time costs money – they can also extend the bidding process. Using thermal break materials in bolted steel connections is still relatively new to many engineers and architects and there is a still a great deal of inexperience that exists while we strive to meet energy code. No one likes change – especially in the construction industry. But even for those who have specified thermal breaks and are comfortable with their use, how can the substitution evaluation process be streamlined or improved?

Unfortunately, thermal break materials are almost always specified in the bid documents by listing their physical properties. As discussed, physical properties as listed on product data sheets are not design criteria. We know that specifying a compressive strength or modulus does not mean that those exact values are required to meet the design intent. So, when they are used as the specification, misconceptions can and often occur. Afterall, what is the design criteria for a thermal break material? How should a thermal break substitution request be evaluated?

The definition of approved equivalent:

“Any material which, in the opinion of the architect, engineer or owner is equal in quality, durability, appearance, strength design, performance or physical dimensions to the material specified and will function in accordance with the design”.

Does the submitted product function the same as the specified product? Structurally, the material should not compress. This is verified via calculation. Regarding energy code, the material needs to have an R value and thickness that will allow the wall or roof assembly to meet the project requirements. This can only be assessed by performing heat flow modeling.

Stating a minimum material property requirement based on calculations and/or analysis to ensure the design intent is met would be a more efficient way to specify thermal break materials. In other words, thermal break materials should be specified using a performance specification.

We can eliminate the dreaded “or equal” phrase and sub requests by using performance specifications rather than listing specific products or physical properties. This would avoid confusion, save time in the evaluation process, and more easily identify materials that are not functionally equivalent. Does the product perform the way the specification requires?

For example, “thermal heat flow modeling has determined that the thermal break material should have a thermal resistance of R 1.5 per inch or greater in order for the wall assembly to meet the required R value of R 25”.

In this way, the products must meet specific end results and only a method for measurement of conformance (test report, test data, calculations, etc.) is required for the submitted product to meet specification and be approved.

About the author: Rob Haley developed the first thermal break material used for steel connections (Fabreeka-TIM) in 2012 while engineering manager at Fabreeka International. He was later co-owner of Armadillo NV where he was responsible for the marketing and research and development of Armatherm thermal break materials. He has over 10 years’ experience with thermal breaks to reduce heat loss due to thermal bridging. email: rob@thermalbridgingsolutions.com

References

Zero Docs, “Specifying Product Substitution Requirements”, 2021

4Specs, “Or Equal….Or Are They?”, Jeffrey Potter

Liz O’Sullivan, “Comments from a Spec Writer”, April 1, 2015