Cast in place concrete balcony thermal break. Egcobox® thermal break assemblies reduce heat loss due to thermal bridging at concrete balcony and canopy connections. This creates continuous insulation within the wall assembly where the exterior insulation is normally interrupted.

Thermal bridging at concrete balcony and canopy connections can reduce the R-value of a wall by nearly 50%. In addition to creating heat loss, the thermal bridging at these connections cools the surface temperature of materials within the building envelope creating condensation risk.

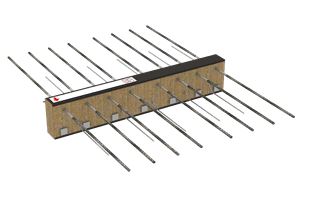

The Egcobox® is a load bearing assembly used as a thermal break to minimize thermal bridging when connecting external reinforced concrete slabs to internal reinforced concrete slabs.

Each assembly is composed of stainless-steel reinforcing bars and an insulating layer of mineral wool with a thickness of 3.15 inch or 4.72 inch. The Egcobox® type depends on the internal forces (shear and moment) to be transferred through the joint for connecting to the reinforced concrete slab. It also can be used for transmitting loads at height offsets.

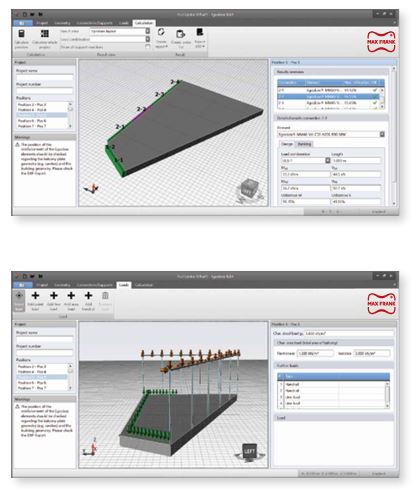

Egcobox® is a structural element, and therefore requires

appropriate structural design to local building codes. The latest generation of Egcobox® software is a tool specifically developed to support this task.

This software is used by Max Frank Engineers to prepare proposals.

The software suggests the most suitable type of Egcobox® for your application and manual changes are easy to make. For accepted proposals, our registered structural engineer provides a final, stamped calculation package with layout drawings.

Alternatively, structural engineers can use Egcobox® technical

information and design tables available in the Egcobox® ‘Design Guide’.

Egcobox® thermal break modules are often installed on precast balconies and canopies to reduce labor costs and time on site.