Thermal Break Material

(TBM-2)

Cladding connection thermal break. Thermal Break Material (TBM-2) is a non-combustible, thermal break that reduces conductive heat loss due to thermal bridging. It provides continuous insulation where structural connections would normally create a thermal bridge in the thermal control layer of the building envelope.

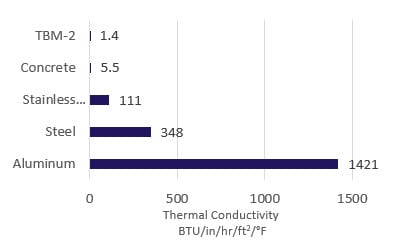

TBM-2 conducts heat 1,000 times less than aluminum, 270 times less than steel and 80 times less than stainless steel. It is compatible with all field applied air barriers, sealants and flashings.

The primary benefit of this thermal break material is that it is non-combustible. As such, it is not necessary to conduct NFPA 285 or ASTM E119 fire rating tests when TBM-2 is incorporated in wall or roof assemblies.

• Cladding Attachments

• Sunshade Brackets

• Roof posts, Anchors

• Roof Edge

• Lintels

• Shelf Angles

• Curtain Wall Plates, Anchors

The thermal conductivity of a material is a function of its conductance which helps determine the rate at which heat flows through that material. Heat flow is also dependent on area and temperature.

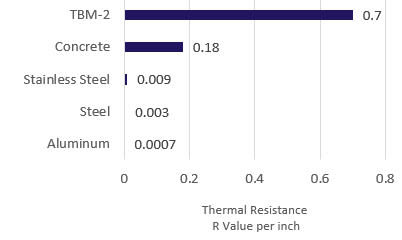

Conductance is a function of thickness, so to be effective at reducing heat flow through a cladding connection, the thickness of the thermal break behind the clip or attachment is important.

TBM-2 thermal break material is available in several thicknesses to accommodate a wide range of connection details. In any connection design, the goal is to use the appropriate thickness/area which helps meet energy code requirements for the wall or roof assembly.