Thermal Break Solutions for Cladding Attachments

Cladding attachment thermal break. Thermal bridging at cladding and façade connections reduces the nominal R-value of exterior insulation and the thermal resistance of a wall assembly. The effective R value of a wall can be reduced by as much as 65% due to thermal bridging at cladding connections as they pass through the building envelope.

Z Girt, Clip and Shelf Angle Connections

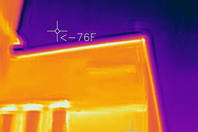

Metallic clips, girts, brackets and shelf angles are highly conductive and create significant heat flow through walls by interrupting continuous insulation. Additionally, the thermal bridging at these attachment locations lowers the surface temperature of materials within the wall assembly. This creates a potential condensation risk if the heat loss brings these temperatures below the dew point.

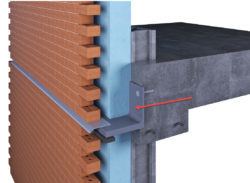

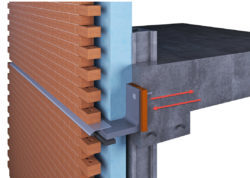

Cement panel attachment brackets and masonry relief angles create a continuous thermal bridge at the steel to concrete connection.

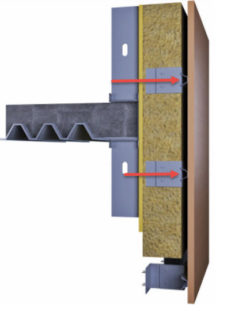

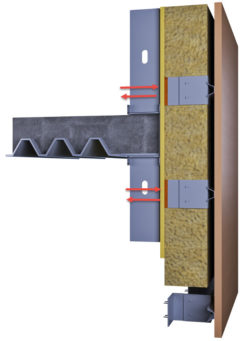

It has been proven that steel z girts create thermal bridging and reduce the R value of a wall. Steel z girts and aluminum clips or brackets interrupt continuous insulation resulting in significant heat loss and energy consumption.

Thermal modeling has shown that using a thermal break at cladding and façade connections will result in a reduction of the heat lost to thermal bridging. This increases the effective R value or thermal resistance of the wall assembly. Thermally broken attachment designs can decrease heat loss as much as 60% at masonry shelf angles and z girts, reducing a wall’s ability to transfer heat.

Steel and aluminum have the ability to conduct heat at a high rate. Due to the thermal conductivity of these materials, they can easily transfer heat at wall connections that pass through the thermal envelope of a building. This is what creates thermal bridging and lower than expected R values of walls.

TBM-1 and TBM-2 thermal break materials can be used behind cladding attachments and relief angles to reduce heat loss and improve wall assembly R values. Exo girt is a composite, thermally broken z girt which significantly reduces the heat loss associated with traditional steel z girts.

Conductance is a function of thickness and temperature difference, so the thickness of a thermal break should be carefully considered. In any connection design using a thermal break, the goal is to use the appropriate thermal conductivity that will help the wall assembly meet energy code requirements.