Thermal Break Solutions for Metal Buildings

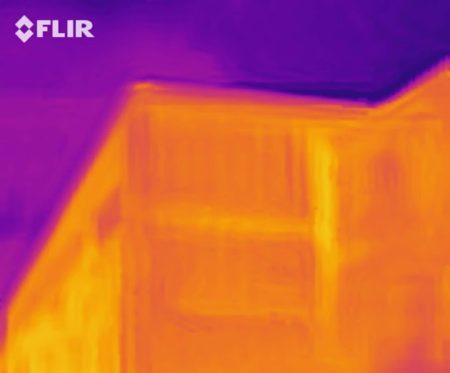

Thermal break for purlin. Thermal bridging in metal building roofs and walls can reduce their R-value by over 50%. In addition to heat loss, the thermal bridging can lower the surface temperature of purlins and girts, creating a risk for condensation in conditioned metal buildings.

Photo/Image credit: Kohta Ueno

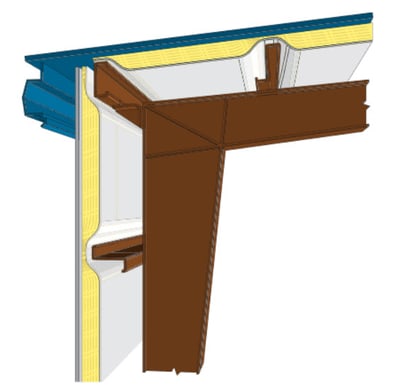

Purlin and Girt Attachments on Metal Buildings

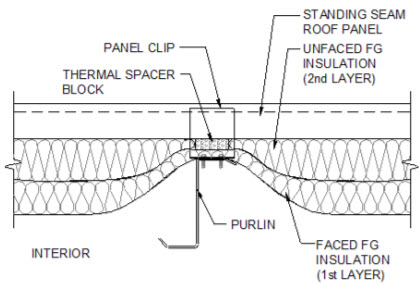

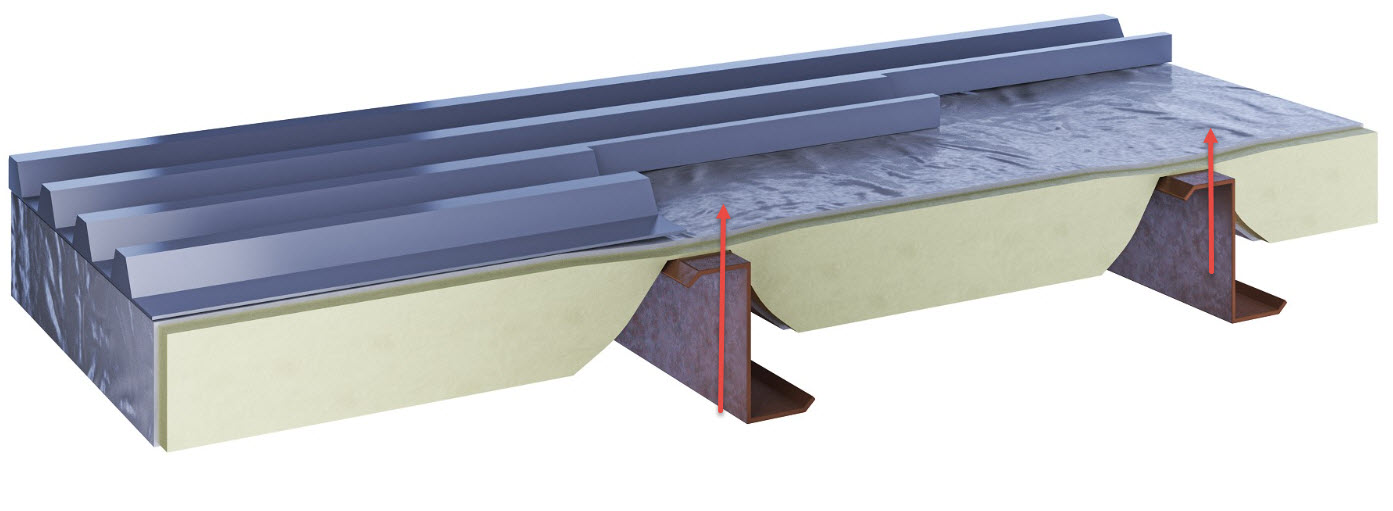

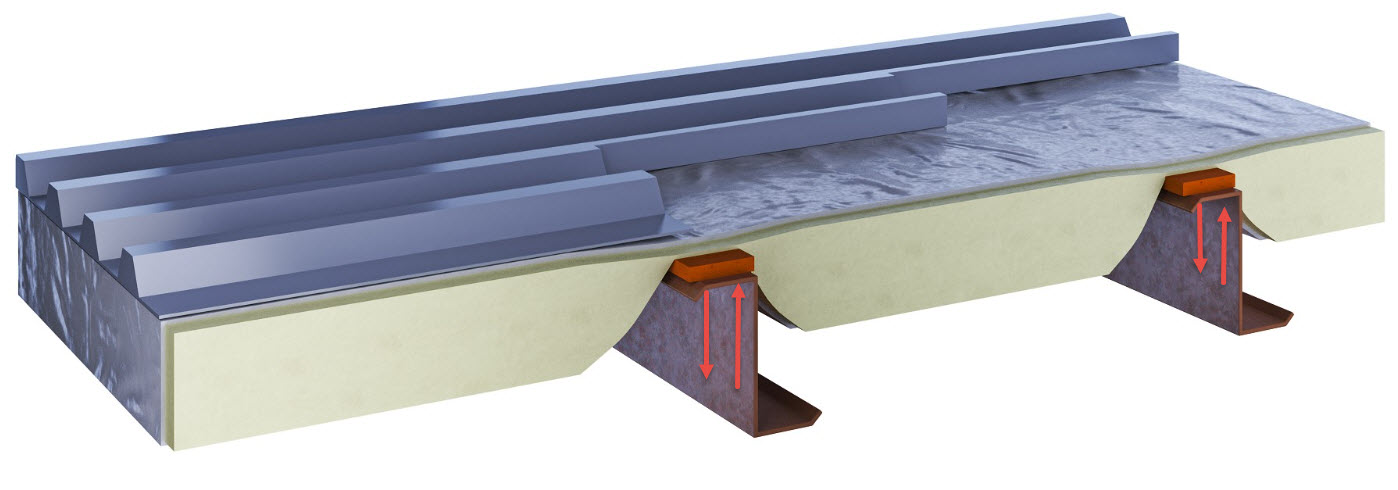

In metal building design, roof panels are installed on roof purlins running across primary frame rafters and wall panels installed on girts running across vertical columns. The batt insulation for the roofs and walls normally runs in between the panels and purlins or girts, getting compressed at the connection points. This creates a thermal bridge at each attachment location, significantly reducing the effective R value of the wall or roof.

Insulation is compressed where metal roof and wall panels are attached to purlins and girts. This creates a thermal bridge and heat loss.

Image credit: Certain Teed

Heat loss at metal wall panel attachment due to thermal bridging.

A structural thermal break or “thermal spacer block” can be used between the metal roof or wall panel and the purlins/girts to reduce thermal bridging. This increases the effective R-value or thermal resistance of the wall or roof assembly. The thermal spacer block must have sufficient compressive strength to support the loading at these connection points.

Thermal spacer blocks provide continuous insulation for the metal building envelope. This improves the U value of the building’s roof and walls and reduces the ability of these assemblies to transfer heat.

Image credit: Pacific Northwest National Laboratory

Steel and Aluminum have the ability to conduct heat at a high rate. Due to the thermal conductivity of these materials, they can easily transfer heat along structural connections that pass through the thermal envelope of a building. This is what creates thermal bridging and the resultant, higher than expected heat loss associated with roof and wall panel connections in metal buildings.

TSBM thermal break material is used as a thermal spacer block at purlin and girt connections to minimize thermal bridging. TSBM can be used in standing seam or through fastened roof assemblies. The material is manufactured in a range of densities with an R value between R 4 and R 5.4

Conductance is a function of thickness and temperature difference, so the thickness of a thermal break should be carefully considered. In any connection design using a thermal break, the goal is to use the appropriate thermal conductivity that will help the wall or roof assembly meet energy code requirements.