Thermal Break Solutions for the Roof

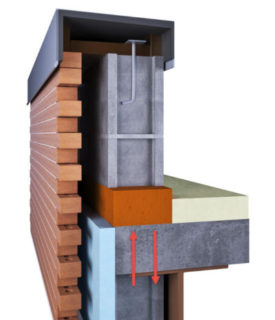

Roof post thermal break. Roof screen post and dunnage connections create a thermal bridge through the roof insulation reducing the roof R value. In addition to the heat lost at these connections, there is also a potential condensation risk within the roof assembly.

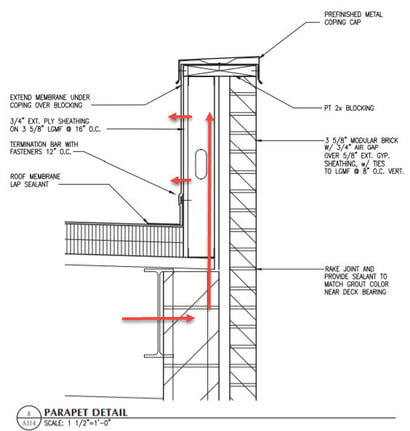

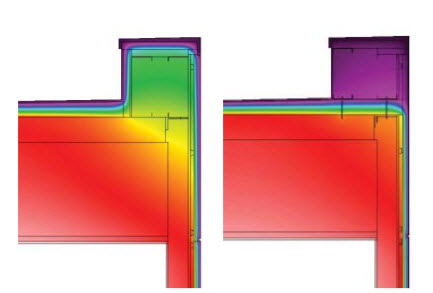

Parapet thermal break. The parapet and roof edge to wall transition are also sources of heat loss within the building envelope. Thermal modeling has shown that the R value of the exterior wall can be reduced by as much as 60% due thermal bridging where the roof and wall meet.

Roof post, anchor, dunnage and parapet connections

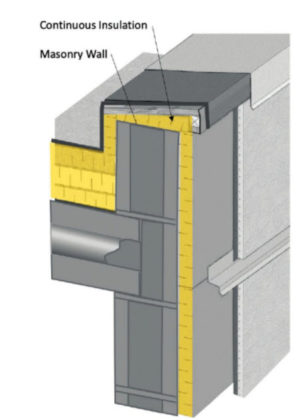

Thermal bridging typically occurs where the roof insulation meets the backside of a parapet structure. Insulation is interrupted or made discontinuous at this interface creating heat loss at the perimeter of the building roof line. To improve the energy efficiency of the building, insulation should be made continuous at parapet wall and roof edge details.

Taller parapets act like cooling fins, drawing heat out of the building where there is a gap between the roof and wall insulation.

Unlike walls and roofs, both sides of parapets are exposed to exterior conditions. In an effort to improve the heat loss at this location, some designs show the use of cavity insulation or “wrapping” the parapet wall. However, because parapet cavities are not conditioned and are located outside of the building enclosure, there remains the risk of potential condensation on material surfaces inside the parapet.

Image credit: Benjamin Meyer, AIA

For short parapet construction with no cavity, insulation can be applied to the backside of the parapet and under the coping to create continuous insulation from roof to wall. Thermal modeling should be done to verify material surface temperatures within the parapet. If there is a risk of condensation, a thermal break should be used under the parapet.

Image credit: Payette

When parapets are “wrapped”, temperatures within can still drop below the dewpoint due to exposure on both sides of the structure. A thermal break will provide more efficient continuous insulation and keep material temperatures above the dew point temperature.

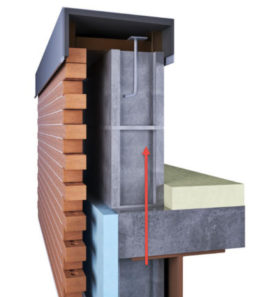

For steel stud, concrete and masonry block parapets, connecting the roof insulation to the wall insulation using a structural thermal break under the parapet wall creates continuous insulation and minimizes the heat loss due to thermal bridging.

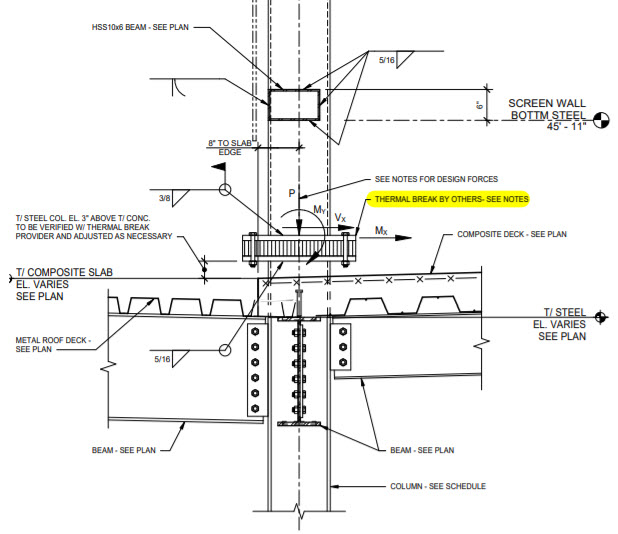

Roof screen post, roof anchor and dunnage connections create a thermal bridge as they penetrate roof insulation where connecting to the main structure. The nominal R value of the roof insulation is reduced in the area of the connection but more importantly, the thermal bridging cools the material surfaces within the roof assembly where condensation can form. This is particularly important for buildings with higher than normal RH levels or cold storage facilities.

Installing a properly designed thermal break at these connections will improve roof insulation R value and prevent the risk of condensation. The location of the thermal break within the roof assembly is important and a dew point analysis should be conducted to be sure all material surface temperatures that are located below the air or vapor barrier are above the dew point temperature.

Roof Post Connection

Structural thermal break material TBM-1

TBM-1 and TBM-2 structural thermal break materials reduce heat loss in steel and aluminum connections that penetrate the roof thermal envelope. Thermoblock thermal break blocks reduce heat loss in parapet applications making insulation at the roof to wall transition continuous and the roof more energy efficient.

Conductance is a function of thickness and temperature difference, so the thickness of a thermal break should be carefully considered. In any connection design using a thermal break, the goal is to use the appropriate thermal conductivity that will help the wall assembly meet energy code requirements.