Thermal Break Solutions for Fenestration Transitions

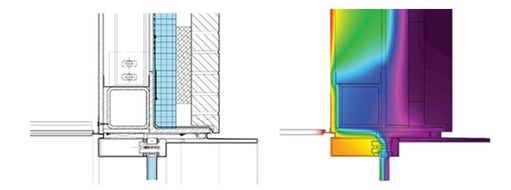

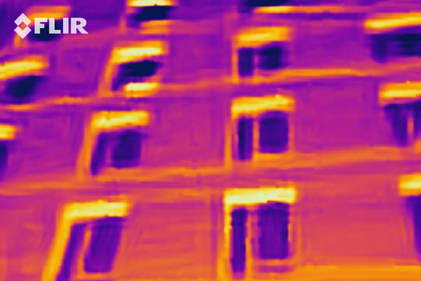

Window opening thermal break. Thermal bridging at fenestration transitions adversely affects window and door U values. Thermal bridging at window openings and transitions occurs at the perimeter of the highly conductive frames where they are attached to the wall opening. This creates a potential condensation risk and can reduce the wall R value by as much as 60%.

Window and door framing connections

Window and door U values do not include the heat loss created by thermal bridging at the transition where the window or door frame meets the wall. The effect of the thermal bridging or the “installed” U value must be assigned to the window or door and accounted for in the energy efficiency of the building.

Thermally broken frames have improved the U values of windows and doors by reducing the conductivity of the frames from outside to inside. However, even the lower conductive framing can be compromised due to flashing details, masonry sills, lintels and the position of the window/door within the wall opening relative to the thermal insulation. In these instances, heat flows around the thermally broken frame, cooling internal surface temperatures.

Heat loss and cooler surface temperatures within a wall assembly due to thermal bridging at a steel lintel over a window. Thermal model credit: Payette

Windows and doors are often recessed within a wall or installed flush with the exterior of the wall. In either case, the fenestration framing, including a door’s threshold can end up in front of or behind the thermal control layer of the wall. Thermally broken frames are then not properly aligned within the wall opening creating a heat loss path or thermal bridge at the frame connections.

Thermal bridging at lintel and frame connections

A thermal break at sill, jamb and header frame attachments in the wall opening will reduce heat loss and prevent condensation from forming on interior framing surfaces.

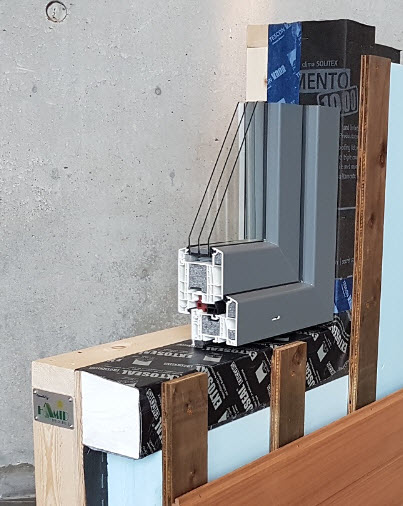

When the window frame is positioned in line with the building external insulation, but proud of the window opening, the window must be supported by a structural element. This structural support for the window must also have a low thermal conductivity to prevent thermal bridging and provide continuous insulation. This is common practice in passive house design. Due to its high strength and thermal resistance properties, Compacfoam is the ideal structural thermal break for this application.

Photo credit: Hamid Design Build

Window transition mock-up showing frame positioned within the insulation layer to avoid thermal bridging or “flanking” at the opening.

Thermal break solution for retrofitting new windows or doors into existing facade openings

Compacfoam and TBM-2 thermal break materials limit thermal bridging at fenestration frame sills, jambs and headers. Compacfoam and TBM-2 can also be used as a thermal break behind masonry lintels. Thermoblock thermal break blocks prevent thermal bridging at door thresholds.

Conductance is a function of thickness and temperature difference, so the thickness of a thermal break should be carefully considered. In any connection design using a thermal break, the goal is to use the appropriate thermal conductivity that will help the wall assembly meet energy code requirements.